Rail Development Group (RDG) was founded in 1999. Our business is supplying the rail and transit industry with new and remanufactured signal equipment of all kinds.

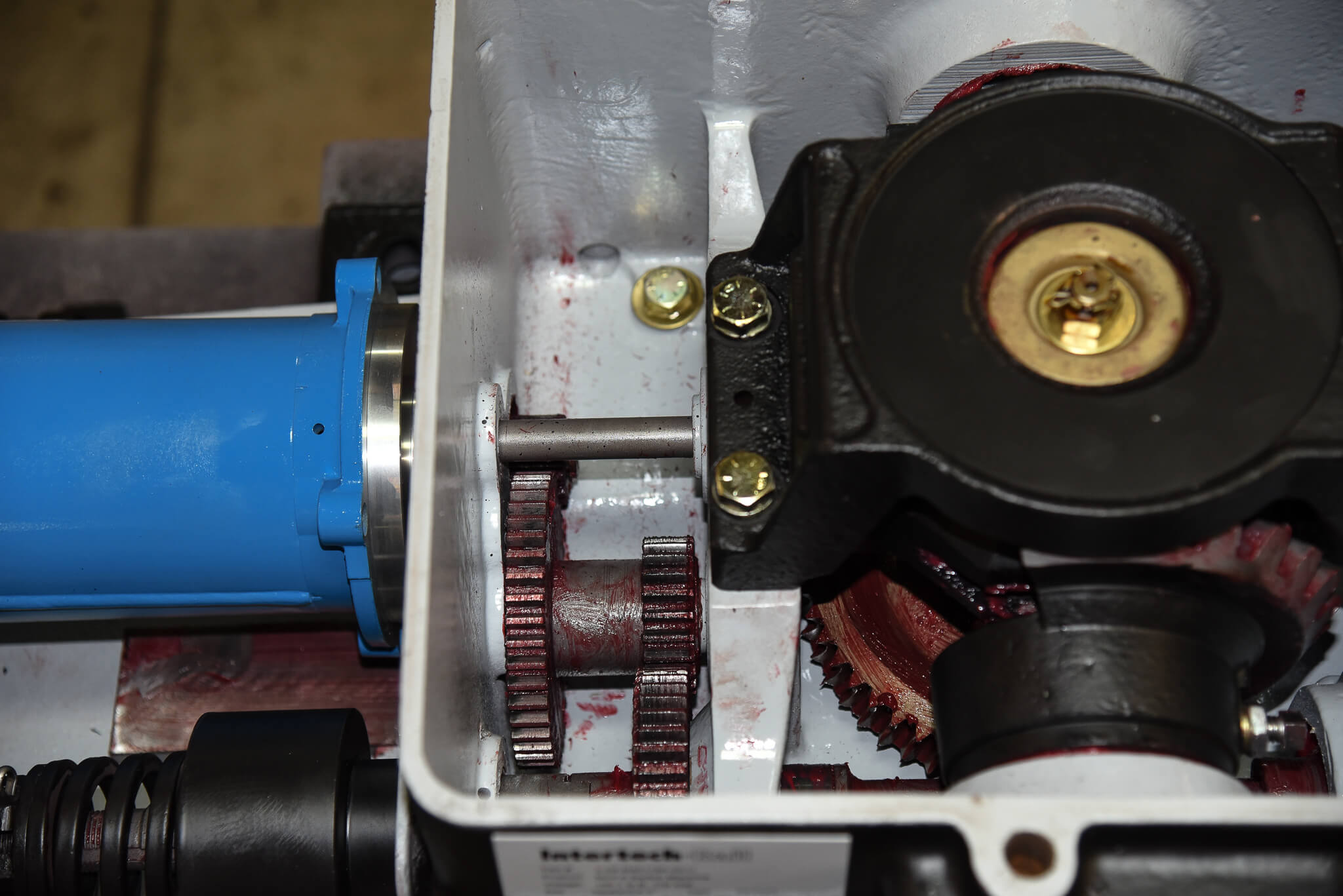

We specialize in remanufacturing power operated switch machines, switch circuit controllers, electric locks, vital relays, and a lot of other equipment that is critical to keeping your rail operating and running safely and smoothly.

We combined our engineering excellence and 200 plus years of railway signaling equipment experience to develop new and innovative replacement equipment for the rail industry – check out our new products section to learn more.

RDG’s objective is to become the industry leader in the signaling train control market for electro-mechanical products and services.

Our promise is simple… To provide the highest quality product and services at an exceptional value.